What is Meant by “Self-Priming” Pump?

When it comes to efficient water management, self-priming pumps stand out as a crucial piece of engineering. Whether you’re tackling flood control, irrigation, or wastewater management, a self-priming pump can make operations smoother and more reliable.

What is a Self-Priming Pump?

The term “self-priming” refers to a pump’s ability to automatically eject air out of the suction line, ensuring uninterrupted flow. A self-priming pump is engineered to handle the air, re-prime itself, and resume pumping without any human intervention.

This contrasts with standard centrifugal pumps, which require external priming to remove air from the system before operations; however, theyare typically more energy-efficient because of the additional energy required for self-priming mechanisms.

How Does a Self-Priming Pump Work?

The goal of the process is to remove the air from the pump casing and suction line, creating a vacuum that draws in the fluid.

- Air handling: When the pump starts, it creates a vacuum that separates the air from the liquid in the pump casing.

- Air ejection: The pump expels the air through the discharge port while simultaneously pulling fluid from the source.

- Priming chamber: Once the air is removed, a continuous flow of liquid kicks in.

This process will continue unless the system is fully drained or an air leak occurs. When the pump isn’t running, fluid is trapped in the pump’s body to prevent it from flowing back to the suction side. It’s important that the self-priming pump is not allowed to run dry at any point.

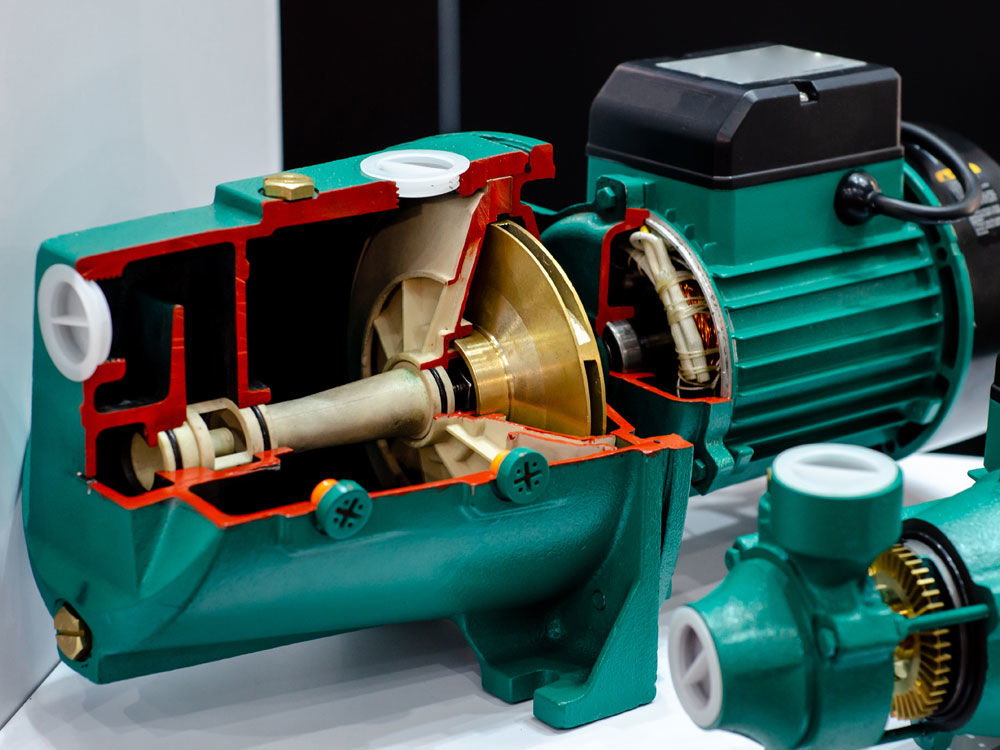

Components That Enable Self-Priming

The individual pieces that allow a self-priming pump to operate can be broken down as such:

- Check valves: Prevent backflow into the suction pipe so the vacuum is maintained.

- Volute casing design: Holds the residual liquid that aids the priming cycle.

- Air separator chamber: Differentiates the air from the liquid.

- Recirculation system: Directs some of the fluid back into the pump casing to aid in priming.

Applications of a Self-Priming Pump

The self-priming design of these pumps makes them a reliable and efficient choice when handling liquids. It’s common to see self-priming pumps in the following applications:

- Flood control

- Irrigation

- Wastewater management

- Industrial applications

- Municipal operations

Conclusion

While self-priming pumps offer a mostly hassle-free experience, repairs and replacements are sometimes necessary. If you’re looking for a replacement pump or parts, HISCO Pump manufactures a wide variety of replacements for many common manufacturers in the industrial market. View our wide surplus inventory or request a quote today.