Mechanical Seals 101: Component vs. Cartridge Seals

Posted by: Hisco Engineering Department

Mechanical seals are an essential part of any pump system and can be found in everything from cooling systems to water pumps, to high-pressure applications. When it comes to choosing the right mechanical seal for your pump, you have a few different options to choose from. Among the most common are component and cartridge seals. In this article, we'll identify the main characteristics of both seal types and how they differ. We'll also discuss the advantages and disadvantages of these two seal types so that you can make an informed decision about which type is best for your needs.

CARTRIDGE VS. COMPONENT MECHANICAL SEALS

Both types of seal have unique advantages and disadvantages, so it's important to understand the differences before making a decision.

Component seals are the more traditional type of seal, and they're typically less expensive than cartridge seals. They're also easier to install and maintain, which makes them a good choice for pumps that are used in relatively simple applications.

Cartridge seals, on the other hand, are designed for more demanding applications. They're more expensive than component seals, but they're much easier to replace than component seals. This is because all the seal's components are housed in a single unit, so there's no need to disassemble the pump when it comes time to replace the seal.

WHAT IS A CARTRIDGE SEAL?

Cartridge seals are designed for more strenuous applications. They tend to cost more than less expensive component seals, but they offer several advantages that can make them worth the extra money.

One of the biggest advantages of cartridge seals is that they're much easier to replace than component seals. This is because all the seal's components are self-contained, so there's no need to disassemble the pump when it comes time to replace the seal, you can simply swap the old seal out with the new one. This can save a significant amount of time and money, especially in applications where downtime is not an option.

Another advantage of cartridge seals is that they're less likely to leak than component seals. This is because the seal's components are less likely to come into contact with one another causing damage, which greatly reduces the risk of leaks.

The disadvantage of this style of seal is that it requires more space and some upfront investment. The high cost of a cartridge seal is due to the fact that it is essentially custom-built for your pump, requiring a lot of information about your system to be gathered beforehand so that a ready-to-use cartridge seal can be produced.

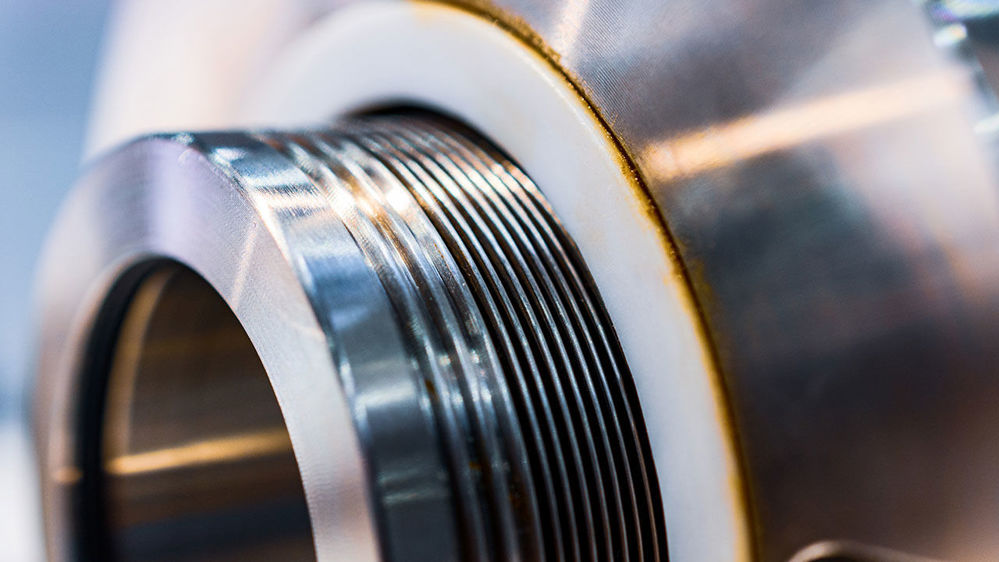

WHAT IS A COMPONENT SEAL?

For simple tasks, component seals are ideal. They contain two distinct dynamic and stationary components. Component seals are not prebuilt and must be installed by a professional engineer because there is an elevated risk of errors that may damage the seal faces, O-rings, or seal axial setting on the pump shaft, which can result in shorter seal life or even immediate failure.

Some advantages of component seals are a lower initial cost investment and shorter installation time since it doesn't require as much pump disassembly or reassembly. Also, despite not being preassembled, component seals have fewer parts than cartridge seals, making them easier to maintain.

There are some disadvantages of component seals as well, because of their simpler design, they may require more frequent maintenance than cartridge seals. Additionally, if not installed correctly, they may cause more wear and tear on the pump, which can lead to a shorter lifespan for both the pump and the seal.

Both types of mechanical seals have their own unique pros and cons, so it's important to understand the differences before making a decision. Component seals are typically less expensive than cartridge seals, but they're also more difficult to replace and may be more prone to leaks. Cartridge seals offer several advantages over component seals, including easier installation and replacement and a reduced likelihood of leaks. If you need help choosing the right seal type for your pump system, contact us for more information or to request a quote.

We look forward to helping you keep your system running smoothly!